The partnership between Fizyr and Dero marks a terrific leap in the world of robotic picking technology. This collaboration aims to revolutionize how industries approach sorting and handling tasks with the aid of advanced robotics. Such an innovation is essential for numerous sectors, especially emerging trends in the space industry, where precision and efficiency are key.

The technology world is buzzing with excitement, as Fizyr teams up with Dero to develop remarkable ‘advanced robotic picking’ systems. Leveraging each other’s strengths, the partnership promises to bring forth unparalleled solutions in robotics. Their collaboration is centered around creating state-of-the-art robotic systems capable of handling complex picking and sorting tasks with ease.

The Motivation Behind the Collaboration

With the ever-growing demand for efficient robotic solutions in industries such as logistics, warehousing, and aerospace, the need for advanced technologies is prominent. Fizyr and Dero recognized the potential to streamline processes and enhance productivity through their joint efforts, setting new standards within the industry.

How Does Robotic Picking Work?

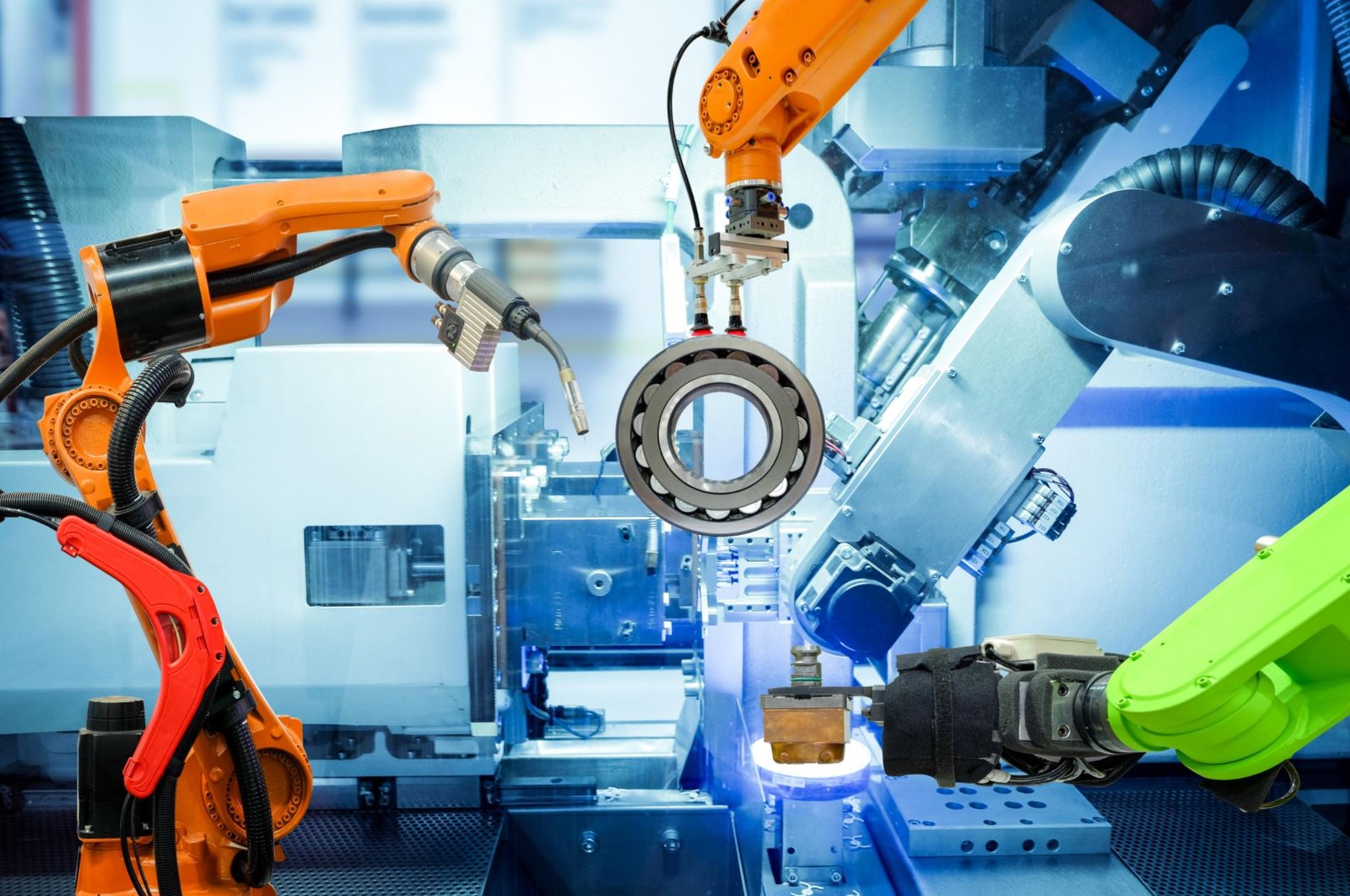

Robotic picking involves the use of automated systems to select and move objects within a defined space. These systems are typically driven by sophisticated algorithms and equipped with sensors to identify and handle items accurately. Dero’s mechanical design expertise, combined with Fizyr’s advanced software solutions, ensures that these robots are both intelligent and efficient.

Key Features of the Technology

1. **Automation**: The robots are designed to work autonomously, reducing the need for human intervention.

2. **Precision**: Using sensors and custom algorithms, the robots can handle objects with great precision, essential for delicate or intricate tasks.

3. **Scalability**: The technology’s modular design allows for easy scalability, making it suitable for businesses of all sizes.

For more on the topic of industrial automation, you can visit this informative article.

Applications in Aerospace

The aerospace industry stands to benefit significantly from advanced robotic picking technologies. Efficient and accurate sorting of materials is crucial in this field. Robots can handle tasks involving complex components, ensuring precision and reducing the possibility of human error. This application aligns with the rise of commercial spaceflight in Florida.

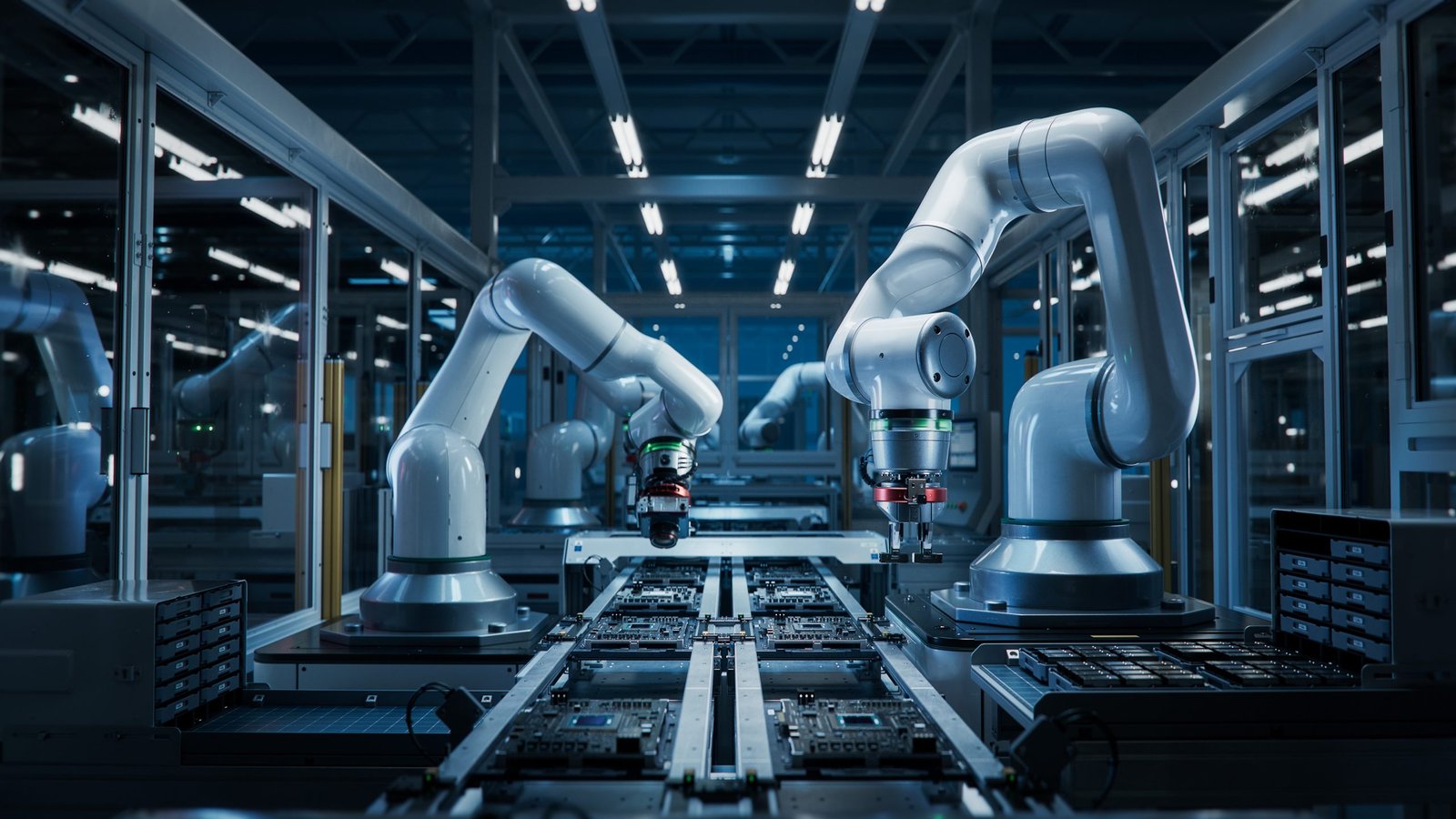

Impact on Aerospace Manufacturing

Integrating robotic picking systems in aerospace manufacturing can lead to increased production efficiency. Automation can handle routine tasks, allowing human workers to focus on more complex activities. This enhances the production line’s speed and quality control.

Challenges and Innovative Solutions

The development of such advanced technology does not come without challenges. These may include ensuring the systems are adaptable to various environments and keeping costs manageable. However, the collaboration between Fizyr and Dero is a significant step toward overcoming these obstacles, paving the way for groundbreaking solutions.

Future Prospects of Robotic Picking

As technology continues to evolve, the potential for new applications and improvements in robotic picking remains immense. Innovations in artificial intelligence and machine learning are expected to further enhance robotic capabilities, making them even more efficient and versatile.

Conclusion

The partnership between Fizyr and Dero to develop ‘advanced robotic picking’ is a significant milestone in the field of automation. With substantial benefits for the aerospace industry and other sectors, this collaborative effort represents a positive step forward in technological advancement. Such initiatives give us a glimpse into a future where robots play an integral role in industrial and commercial processes, improving both precision and productivity.

Frequently Asked Questions (FAQ)

1. What makes robotic picking beneficial over traditional methods?

Robotics offers higher precision, efficiency, and scalability in handling repetitive tasks compared to traditional manual methods, allowing human workers to focus on complex and skill-intensive tasks.

2. How significant is the impact of robotic picking on production costs?

While initial investments might be high, robotic picking helps reduce long-term operational costs by minimizing errors and increasing efficiency in production lines.

3. Are robotic picking systems customizable for different industries?

Yes, these systems are designed to be flexible and scalable, making them suitable for various industries including logistics, manufacturing, and aerospace, to name a few.