The manufacturing sector is undergoing a transformation as artificial intelligence becomes a key driver of efficiency and quality. AI powered inspection systems are at the forefront of this revolution, offering manufacturers new ways to detect defects, maintain consistency, and reduce waste. These advanced solutions leverage machine learning, computer vision, and data analytics to automate quality assurance processes that were once manual and time-consuming.

By integrating intelligent inspection technologies into production lines, companies can achieve higher accuracy, faster throughput, and real-time insights. This not only improves product quality but also enhances competitiveness in a rapidly evolving industry. For a deeper understanding of how sensors contribute to this technological shift, explore the role of sensors in AI manufacturing and their impact on efficient automation.

Understanding Intelligent Inspection Technologies

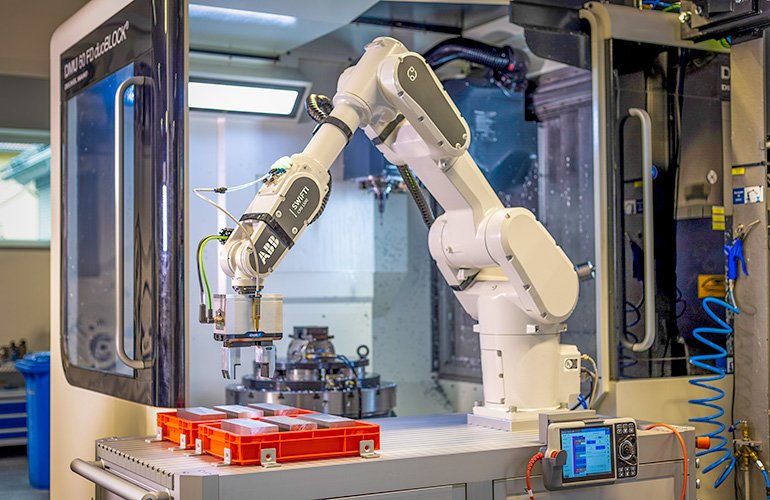

At its core, an AI powered inspection system combines advanced algorithms with high-resolution cameras and sensors to analyze products as they move through manufacturing lines. Unlike traditional inspection, which relies on human operators or basic automation, these systems can learn from data, adapt to new patterns, and identify subtle defects that might be missed otherwise.

The integration of machine vision in manufacturing has been a game-changer. Machine vision enables the rapid capture and processing of images, while AI interprets these images to detect flaws, measure dimensions, and verify assembly. This synergy results in more reliable and scalable quality control.

Key Benefits of Automated Quality Control

Manufacturers adopting AI-driven inspection solutions experience several advantages:

- Increased Accuracy: AI algorithms can detect even the smallest deviations from quality standards, reducing the risk of defective products reaching customers.

- Consistent Results: Unlike human inspectors, AI systems do not tire or lose focus, ensuring uniform inspection around the clock.

- Faster Throughput: Automated inspection can keep pace with high-speed production lines, minimizing bottlenecks and downtime.

- Cost Savings: By catching defects early, companies can avoid costly recalls, rework, and material waste.

- Data-Driven Insights: These systems generate valuable data that can be used to improve processes, identify trends, and support continuous improvement initiatives.

For more on how these technologies are shaping product quality, see our guide on how AI improves product quality across production lines.

How AI-Powered Inspection Systems Work

The operation of these systems typically involves several stages:

- Image Acquisition: Cameras and sensors capture detailed images or data from products as they pass by on the line.

- Preprocessing: Raw data is cleaned and enhanced to highlight features relevant for inspection.

- Feature Extraction: The system identifies key characteristics, such as shape, color, texture, or dimensions.

- Defect Detection: AI models compare extracted features to predefined standards, flagging anomalies or deviations.

- Decision Making: Based on the analysis, the system can trigger actions like sorting, rejection, or alerts for manual review.

The adaptability of these solutions allows them to handle a wide range of products, from electronics and automotive components to food and pharmaceuticals.

Applications Across Manufacturing Sectors

The versatility of AI powered inspection systems makes them suitable for various industries:

- Automotive: Detecting surface defects, verifying assembly, and ensuring safety-critical components meet specifications.

- Electronics: Inspecting printed circuit boards for soldering errors, missing components, or micro-cracks.

- Pharmaceuticals: Checking packaging integrity, labeling accuracy, and contamination in drug manufacturing.

- Food and Beverage: Monitoring packaging, fill levels, and detecting foreign objects or spoilage.

- Consumer Goods: Ensuring cosmetic quality and functional performance of household products.

As manufacturing processes become more complex, the need for scalable and adaptive inspection grows. AI-driven solutions are uniquely positioned to address these evolving demands.

Challenges and Considerations When Implementing AI Inspection

While the benefits are significant, deploying intelligent inspection systems comes with challenges:

- Data Quality: AI models require large volumes of high-quality data for training and validation. Poor data can lead to inaccurate results.

- Integration: Retrofitting existing production lines with new technology may require adjustments to workflows and infrastructure.

- Change Management: Employees need training to work alongside AI systems and interpret their outputs effectively.

- Cost: Initial investment in hardware, software, and integration can be substantial, though long-term savings often offset these expenses.

- Ongoing Maintenance: AI models must be updated regularly to adapt to new products, materials, or defect types.

Manufacturers should approach implementation with a clear strategy, focusing on areas where automation will deliver the greatest impact. Leveraging data analytics in smart manufacturing can further enhance the value of AI inspection by uncovering process improvements and supporting predictive maintenance.

Future Trends in Automated Quality Assurance

The evolution of AI powered inspection systems is closely linked to advances in deep learning, edge computing, and industrial IoT. Some emerging trends include:

- Real-Time Decision Making: With faster processors and edge AI, inspection results can be acted upon instantly, reducing delays and improving responsiveness.

- Self-Learning Systems: AI models are becoming more autonomous, capable of learning from new data without extensive retraining.

- Integration with Factory Networks: Inspection data is increasingly shared across enterprise systems, supporting traceability and regulatory compliance.

- Collaborative Robots: Cobots equipped with vision and AI are working alongside humans to handle complex inspection tasks safely and efficiently.

For a broader perspective on how AI is shaping manufacturing, the impact of artificial intelligence in manufacturing offers valuable insights into current trends and future possibilities.

Best Practices for Adopting AI-Driven Inspection Solutions

To maximize the return on investment and ensure successful deployment, manufacturers should consider the following best practices:

- Start Small: Pilot AI inspection on a single line or product before scaling up to the entire facility.

- Collaborate with Experts: Work with technology providers and integrators who understand both AI and your specific manufacturing needs.

- Invest in Training: Equip staff with the skills to operate, maintain, and interpret AI systems.

- Monitor and Improve: Continuously collect feedback and performance data to refine models and processes.

- Ensure Data Security: Protect sensitive production data and comply with relevant regulations.

As AI continues to advance, staying informed about the latest developments—such as AI in real time monitoring—will help manufacturers remain competitive and agile.

Frequently Asked Questions

What types of defects can AI-based inspection systems detect?

These systems can identify a wide range of issues, including surface scratches, dimensional inaccuracies, missing or misaligned components, color inconsistencies, contamination, and more. The specific capabilities depend on the training data and configuration of the AI model.

How do AI inspection systems differ from traditional automated inspection?

Traditional automated inspection often relies on fixed rules and simple image processing, which can miss complex or subtle defects. AI-driven solutions use machine learning to recognize patterns and adapt to new defect types, resulting in higher accuracy and flexibility.

Is it possible to retrofit existing production lines with AI inspection technology?

Yes, many modern AI inspection solutions are designed for integration with existing equipment. However, successful implementation may require adjustments to lighting, camera placement, and data infrastructure to ensure optimal performance.