Artificial intelligence is rapidly transforming the manufacturing sector, driving significant changes in how factories operate and how efficiently goods are produced. As companies seek to remain competitive in a global market, the impact of AI on industrial productivity has become a central focus for decision-makers and engineers alike. From predictive maintenance to intelligent automation, AI technologies are unlocking new levels of efficiency, quality, and flexibility across the industrial landscape.

This article explores the core ways AI is reshaping productivity in factories, examines practical applications, and offers insights into how organizations can harness these advancements to streamline their operations. For those interested in seeing real-world implementations, you can review examples of AI in manufacturing to understand how these concepts are being applied today.

How Artificial Intelligence Boosts Factory Efficiency

The integration of AI into manufacturing environments is revolutionizing traditional workflows. By leveraging machine learning algorithms, computer vision, and advanced analytics, factories are able to optimize processes and reduce waste. These technologies enable systems to learn from data, adapt to changing conditions, and make decisions faster than human operators alone.

Key areas where AI is making a difference include:

- Predictive maintenance to anticipate equipment failures and schedule repairs proactively

- Automated quality control using computer vision for defect detection

- Dynamic scheduling and resource allocation based on real-time data

- Energy usage optimization to lower operational costs

- Supply chain forecasting and inventory management

AI-Driven Automation and Its Effects on Productivity

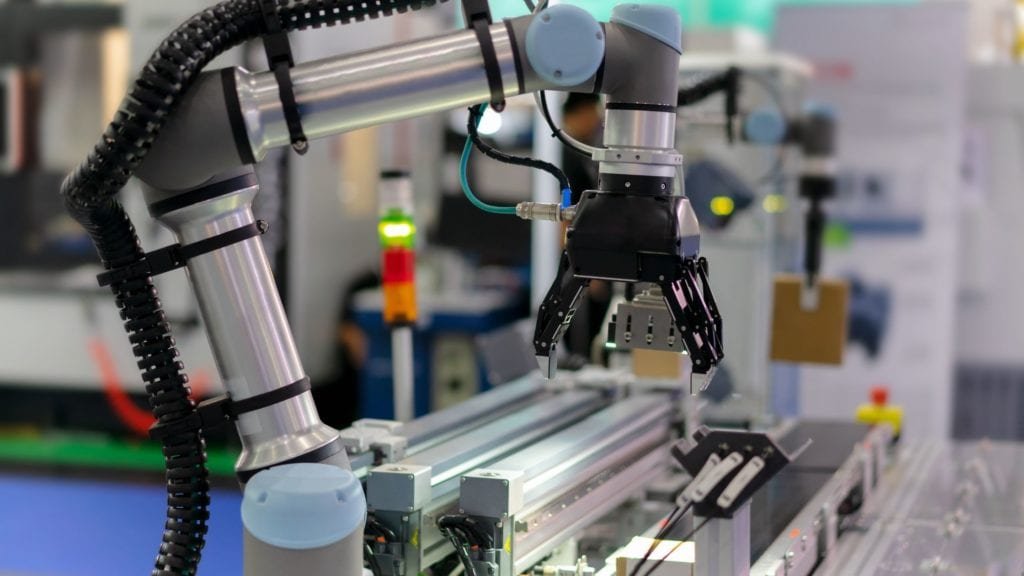

Automation powered by artificial intelligence is one of the most visible changes in modern factories. Robotic arms, autonomous vehicles, and intelligent sorting systems are now commonplace on production lines. These solutions not only speed up repetitive tasks but also improve consistency and safety.

According to industry experts, the adoption of AI-driven automation can lead to:

- Significant reductions in cycle times

- Lower error rates and improved product quality

- Enhanced worker safety by reducing exposure to hazardous environments

- Greater flexibility to adapt to new product designs or changes in demand

For a deeper dive into how automation and AI work together to streamline production, see the article on ai and automation in manufacturing.

Data-Driven Decision Making in Industrial Settings

One of the most profound benefits of AI in manufacturing is the ability to turn vast amounts of operational data into actionable insights. By analyzing sensor data, machine logs, and production statistics, AI systems can identify inefficiencies, predict bottlenecks, and recommend process improvements.

This data-driven approach empowers plant managers to make informed decisions quickly, leading to:

- Reduced downtime through predictive analytics

- Optimized resource allocation

- Faster response to market changes and customer demands

- Continuous improvement through real-time feedback loops

If you’re interested in the technical side of how these systems work, the resource on how machine learning works in factories provides a clear explanation of the underlying principles.

Challenges and Considerations in AI Adoption

While the benefits are substantial, implementing AI in industrial environments is not without its challenges. Companies must address issues such as data quality, integration with legacy systems, workforce training, and cybersecurity. A thoughtful approach to change management is essential to ensure that employees are equipped to work alongside intelligent systems.

Additionally, organizations should consider the ethical implications of automation, including its impact on jobs and the need for upskilling. Transparent communication and a commitment to responsible AI use are key to building trust with both workers and customers.

Future Trends in AI-Enhanced Manufacturing

The role of AI in boosting productivity is expected to grow as new technologies emerge. Developments in edge computing, collaborative robotics, and generative AI will further expand the possibilities for smart factories. Manufacturers that stay ahead of these trends will be better positioned to capitalize on new efficiencies and market opportunities.

For a forward-looking perspective, explore the future of ai in manufacturing to see what’s on the horizon for industrial innovation.

Practical Steps for Implementing AI in Factories

To successfully integrate AI and realize productivity gains, manufacturers should follow a structured approach:

- Assess current operations to identify areas with the highest potential for improvement.

- Invest in high-quality data collection and management systems.

- Start with pilot projects to demonstrate value and build organizational buy-in.

- Provide training and support for staff to adapt to new technologies.

- Scale successful initiatives across the organization while continuously monitoring outcomes.

For more details on maximizing efficiency, the guide on how ai improves production efficiency offers practical advice and strategies.

Industry Resources and Further Reading

Staying informed about the latest advancements is crucial for any organization aiming to leverage AI for industrial productivity. Leading technology providers and research institutions regularly publish insights and case studies on this topic. For a comprehensive overview, the IBM resource on AI in manufacturing covers trends, technologies, and best practices from across the industry.

Frequently Asked Questions

How does AI improve productivity in manufacturing environments?

AI enhances productivity by automating repetitive tasks, predicting equipment failures, optimizing resource allocation, and enabling real-time quality control. These improvements lead to faster production cycles, reduced downtime, and higher product quality.

What are the main barriers to adopting AI in factories?

Common challenges include integrating AI with existing systems, ensuring data quality, managing cybersecurity risks, and providing adequate training for the workforce. Overcoming these barriers requires careful planning and investment in both technology and people.

Can small and medium-sized manufacturers benefit from AI?

Yes, AI solutions are increasingly accessible to organizations of all sizes. Cloud-based platforms, modular AI tools, and scalable pilot projects allow smaller manufacturers to start with targeted applications and expand as they see results.