Unplanned equipment failures can disrupt production, increase costs, and reduce overall efficiency in manufacturing and industrial settings. To address these challenges, organizations are turning to predictive maintenance powered by artificial intelligence. This approach uses advanced data analysis and machine learning to anticipate when equipment is likely to fail, allowing for timely interventions that keep operations running smoothly.

By leveraging real-time data and AI-driven insights, businesses can move beyond traditional maintenance schedules and respond proactively to emerging issues. This guide explores the mechanics of how predictive maintenance works with AI, its benefits, and practical steps for implementation.

For readers interested in broader applications, you can find examples of AI in manufacturing to see how similar technologies are transforming other areas of industry.

Understanding Predictive Maintenance and Artificial Intelligence

Predictive maintenance is a strategy that uses data from equipment sensors, historical records, and operational logs to forecast when maintenance should be performed. Unlike reactive or scheduled maintenance, this method aims to prevent failures before they occur, minimizing both downtime and unnecessary servicing.

Artificial intelligence enhances this process by analyzing vast amounts of data, identifying patterns, and making accurate predictions about equipment health. Machine learning algorithms can detect subtle changes in vibration, temperature, or performance that may indicate an impending issue.

Key Components of AI-Driven Maintenance Systems

To understand how predictive maintenance works with AI, it’s helpful to break down the core elements involved:

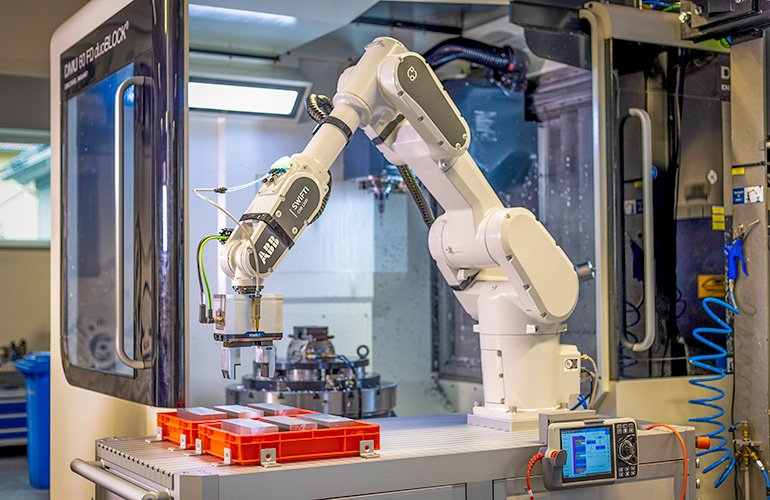

- Data Collection: Sensors installed on machinery collect real-time data such as temperature, vibration, pressure, and energy consumption.

- Data Integration: Collected data is transmitted to a centralized platform where it is aggregated and organized for analysis.

- AI and Machine Learning Models: Algorithms process the data, learning from both normal and abnormal patterns to predict future failures.

- Alerting and Visualization: When the system detects a potential issue, it generates alerts and visual dashboards for maintenance teams to review.

- Automated Decision-Making: Some advanced systems can automatically schedule maintenance or shut down equipment to prevent damage.

Benefits of Using AI for Equipment Monitoring

Implementing AI-based predictive maintenance offers several advantages over traditional approaches:

- Reduced Downtime: By catching issues early, organizations can avoid costly unplanned outages and keep production lines running smoothly.

- Lower Maintenance Costs: Maintenance is performed only when needed, reducing unnecessary labor and parts replacement.

- Extended Equipment Life: Timely interventions help prevent catastrophic failures, increasing the lifespan of critical assets.

- Improved Safety: Early detection of faults reduces the risk of accidents caused by equipment malfunction.

- Data-Driven Decision Making: Maintenance teams gain actionable insights, enabling better planning and resource allocation.

These benefits are driving adoption across industries. For a deeper dive into how digital transformation is shaping the sector, see this resource on the role of AI in manufacturing.

How Machine Learning Powers Predictive Maintenance

The heart of AI-based predictive maintenance lies in machine learning. These algorithms are trained on historical equipment data to recognize what normal operation looks like and to spot deviations that signal potential problems.

Common machine learning techniques used include:

- Anomaly Detection: Identifies unusual patterns in sensor data that may indicate wear or malfunction.

- Regression Analysis: Estimates the remaining useful life of components based on observed trends.

- Classification: Categorizes events or sensor readings as normal or abnormal, triggering alerts when thresholds are crossed.

These models improve over time as more data is collected, becoming increasingly accurate at predicting failures. For those interested in the technical side, exploring how machine learning works in factories can provide further insights into these processes.

Steps to Implement AI-Powered Maintenance in Your Facility

Adopting an AI-driven maintenance strategy involves several key steps:

- Assess Current Infrastructure: Evaluate existing equipment and identify which assets would benefit most from predictive monitoring.

- Install Sensors: Equip machinery with IoT sensors capable of capturing relevant operational data.

- Integrate Data Systems: Ensure that data from sensors can be collected, stored, and accessed by AI platforms.

- Choose or Develop AI Models: Select machine learning algorithms suited to your equipment and operational needs.

- Train and Validate Models: Use historical and real-time data to train models, validating their accuracy before deployment.

- Set Up Alerts and Dashboards: Configure the system to notify maintenance teams of potential issues and provide clear visualizations.

- Monitor and Refine: Continuously monitor system performance and refine models as more data becomes available.

For organizations looking to boost efficiency, integrating AI with existing production systems can be transformative. Learn more about how AI improves production efficiency in modern factories.

Challenges and Considerations for Successful Adoption

While the advantages are clear, there are challenges to consider when deploying AI-based maintenance solutions:

- Data Quality: Inaccurate or incomplete data can lead to poor predictions. Ensuring high-quality sensor data is essential.

- Integration Complexity: Connecting legacy equipment and disparate systems may require significant investment and technical expertise.

- Change Management: Maintenance teams may need training to interpret AI-driven insights and adapt to new workflows.

- Cybersecurity: More connected devices increase the risk of cyber threats, necessitating robust security measures.

- Cost: Initial setup costs can be high, but long-term savings and efficiency gains often justify the investment.

Addressing these factors early in the planning process will help ensure a smoother transition and maximize the benefits of predictive maintenance.

FAQ: Predictive Maintenance and Artificial Intelligence

What types of equipment benefit most from AI-powered maintenance?

High-value assets with complex operational profiles, such as industrial robots, turbines, pumps, and conveyor systems, gain the most from predictive monitoring. These machines often have multiple failure points and generate large volumes of data, making them ideal candidates for AI analysis.

How does predictive maintenance differ from preventive maintenance?

Preventive maintenance relies on scheduled servicing based on time or usage intervals, regardless of equipment condition. Predictive maintenance, enhanced by AI, uses real-time data and analytics to determine the optimal time for maintenance, reducing unnecessary interventions and preventing unexpected failures.

Is it necessary to replace all existing equipment to use AI-based maintenance?

No, many predictive maintenance solutions can be retrofitted to existing machinery by adding sensors and integrating with current data systems. However, some older equipment may require upgrades to support data collection and connectivity.

Where can I learn more about future trends in AI for industry?

For further reading on emerging technologies and their impact on manufacturing, see this overview of the future of AI in manufacturing.