In modern manufacturing, maintaining seamless operations and minimizing inefficiencies are critical for competitiveness. Artificial intelligence (AI) is transforming how organizations monitor, analyze, and optimize their production processes. By leveraging advanced algorithms, real-time data, and machine learning, AI enables manufacturers to gain unprecedented visibility into every stage of their workflow. Understanding how AI tracks production flow is essential for businesses aiming to enhance operational control, reduce costs, and respond swiftly to changing demands.

This guide explores the core mechanisms behind AI-powered production tracking, the benefits it delivers, and practical steps for implementation. For those interested in related innovations, you may also want to read about how digital twins use AI to optimize manufacturing operations.

Understanding AI-Driven Production Monitoring

Traditional production monitoring often relies on manual data entry, periodic checks, and isolated systems. These methods can lead to delays, errors, and limited insight into real-time operations. In contrast, AI-driven solutions utilize sensors, cameras, and connected devices to gather continuous data from the factory floor. This information is processed by machine learning models that detect patterns, identify bottlenecks, and predict potential disruptions.

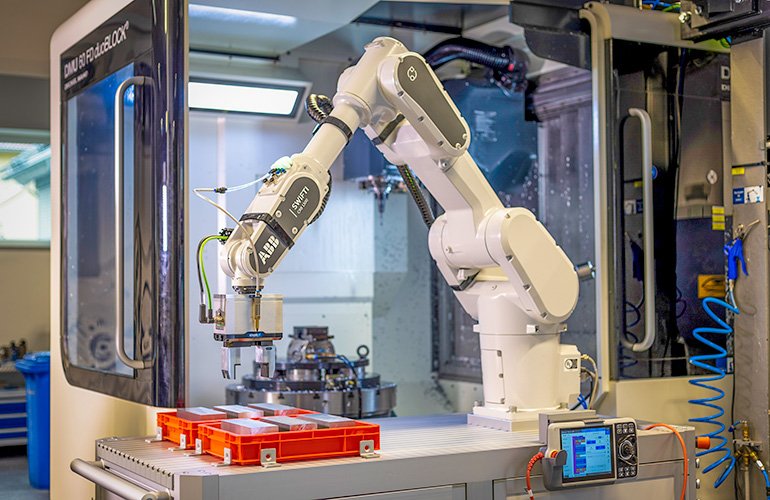

The integration of AI with the industrial internet of things and ai has accelerated the shift toward smarter, more connected factories. By combining sensor data with AI analytics, manufacturers can automatically track material movement, machine status, and workforce activities across the entire production line.

Key Technologies Behind Automated Production Flow Tracking

Several technologies work together to enable AI-based production flow tracking:

- IoT Sensors: Devices embedded in machinery and equipment collect data on temperature, vibration, speed, and more.

- Computer Vision: Cameras combined with AI algorithms monitor assembly lines, detect defects, and verify product quality in real time.

- Machine Learning: Algorithms analyze large volumes of production data to uncover trends, optimize scheduling, and forecast maintenance needs.

- Cloud Computing: Centralizes data storage and processing, enabling remote monitoring and advanced analytics.

- Integration Platforms: Connect disparate systems, ensuring seamless data flow between machines, ERP systems, and analytics dashboards.

By leveraging these technologies, manufacturers can achieve a holistic view of their operations and respond proactively to issues as they arise.

How AI Tracks Production Flow in Real Time

The core advantage of AI in production environments is its ability to provide real-time insights. Here’s how the process typically works:

- Data Collection: Sensors and devices continuously gather information from machines, conveyors, and workstations.

- Data Processing: AI algorithms process raw data, filtering out noise and highlighting relevant metrics such as cycle times, throughput, and downtime.

- Pattern Recognition: Machine learning models identify normal operating patterns and flag anomalies, such as unexpected slowdowns or deviations from standard procedures.

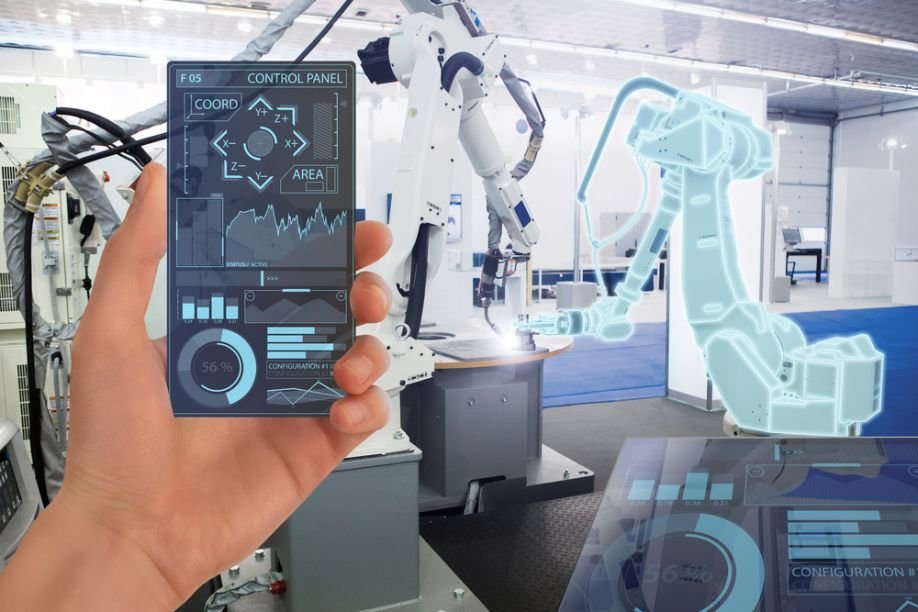

- Visualization: Dashboards display key performance indicators (KPIs), allowing managers to monitor the flow of materials and products at a glance.

- Automated Alerts: When issues are detected, the system can trigger alerts or even initiate corrective actions automatically.

This continuous feedback loop empowers teams to make data-driven decisions and maintain optimal production flow.

Benefits of AI-Powered Production Flow Management

Adopting AI for production flow monitoring offers several tangible benefits:

- Increased Efficiency: Automated tracking reduces manual intervention and streamlines workflows.

- Reduced Downtime: Predictive analytics help anticipate equipment failures, allowing for proactive maintenance and minimizing unplanned stops.

- Improved Quality: Real-time monitoring detects defects early, reducing waste and ensuring consistent product standards.

- Enhanced Visibility: Managers gain a comprehensive view of operations, making it easier to identify improvement opportunities.

- Faster Response: Automated alerts and insights enable quick action when issues arise, minimizing the impact on production.

For a deeper dive into how predictive analytics can minimize downtime, see our article on how AI predicts equipment breakdowns.

Implementing AI in Your Production Environment

Transitioning to AI-powered production tracking requires careful planning and execution. Here are key steps to consider:

- Assess Current Processes: Map out your existing production flow and identify pain points or inefficiencies.

- Define Objectives: Set clear goals for what you want to achieve—whether it’s reducing downtime, improving quality, or increasing throughput.

- Choose the Right Technologies: Select sensors, AI platforms, and integration tools that align with your operational needs.

- Integrate Systems: Ensure seamless data flow between machines, analytics platforms, and management dashboards.

- Train Staff: Equip your team with the skills needed to interpret AI-driven insights and act on recommendations.

- Monitor and Refine: Continuously evaluate system performance and make adjustments to maximize value.

Many manufacturers also benefit from combining AI with IoT solutions. Learn more about the benefits of combining AI and IoT in manufacturing for a holistic approach.

Challenges and Considerations in AI-Based Production Tracking

While the advantages are significant, implementing AI for production monitoring comes with challenges:

- Data Quality: Inaccurate or incomplete data can undermine AI effectiveness. Ensuring sensor calibration and data integrity is essential.

- Integration Complexity: Connecting legacy equipment and disparate systems may require custom solutions or middleware.

- Change Management: Employees may need training and support to adapt to new workflows and technologies.

- Cybersecurity: Increased connectivity introduces new security risks that must be addressed proactively.

- Cost: Initial investment in sensors, software, and training can be substantial, though long-term ROI is often strong.

Addressing these challenges early can smooth the transition and help realize the full benefits of AI-driven operational control.

Industry Examples and Further Reading

Leading manufacturers across automotive, electronics, and consumer goods sectors are already leveraging AI to optimize their production flow. For example, some organizations use computer vision to monitor assembly lines, while others deploy predictive maintenance systems to reduce equipment failures.

For more insights on how AI is transforming manufacturing, explore this comprehensive overview of AI in manufacturing.

If you’re interested in how AI integrates with IoT to enhance efficiency, our article on how AI integrates with IoT provides practical examples and strategies.

Frequently Asked Questions

What types of data does AI use to monitor production flow?

AI systems rely on a wide range of data sources, including sensor readings (temperature, vibration, speed), machine logs, camera feeds, barcode scans, and ERP system data. This information is processed to provide real-time insights and optimize workflow.

How does AI help reduce downtime in manufacturing?

By analyzing historical and real-time data, AI can predict when equipment is likely to fail or require maintenance. This allows manufacturers to schedule repairs proactively, minimizing unplanned downtime and keeping production on track.

Is it necessary to replace all existing equipment to implement AI-based tracking?

Not necessarily. Many AI solutions can be integrated with existing machinery using retrofit sensors and connectivity modules. However, some legacy systems may require upgrades or additional integration work to enable seamless data collection and analysis.