The integration of artificial intelligence with additive manufacturing is transforming the way industries approach precision and reliability in production. As 3D printing becomes more prevalent in sectors like aerospace, healthcare, and automotive, ensuring consistent quality and minimizing errors has become a top priority. AI-driven solutions are now playing a crucial role in monitoring, analyzing, and optimizing every stage of the 3D printing process.

By leveraging machine learning algorithms, real-time data analysis, and predictive modeling, manufacturers can detect issues early, reduce waste, and achieve higher accuracy in their printed components. This guide explores the many ways intelligent systems are enhancing the standards of additive manufacturing, from design optimization to post-production inspection.

For those interested in broader applications of smart manufacturing, our article on how digital twins use AI provides additional insights into the digital transformation of industrial operations.

AI-Driven Monitoring for Enhanced Print Quality

One of the most significant advantages of incorporating AI into 3D printing is the ability to monitor the printing process in real time. Traditional quality control methods often rely on post-production inspection, which can result in wasted materials and time if defects are discovered late. In contrast, AI-powered systems use sensors and cameras to collect data throughout the build, allowing for immediate detection of anomalies such as layer misalignment, warping, or incomplete fusion.

Machine learning models are trained to recognize patterns associated with high-quality prints as well as common defects. When an issue is detected, the system can automatically pause the process or adjust parameters to correct the problem. This proactive approach not only reduces the likelihood of failed prints but also helps maintain consistent standards across multiple production runs.

Optimizing Design and Process Parameters with AI

Achieving optimal results in additive manufacturing requires careful calibration of numerous variables, including temperature, speed, material flow, and geometry. AI excels at analyzing vast datasets to identify the best combinations of these parameters for specific applications. By simulating different scenarios and learning from previous outcomes, intelligent algorithms can recommend adjustments that improve both quality and efficiency.

For instance, generative design tools powered by AI can automatically create complex structures that maximize strength while minimizing material usage. These tools consider the intended function, load requirements, and manufacturing constraints, producing designs that would be difficult or impossible to achieve manually. As a result, manufacturers can produce lighter, stronger, and more reliable parts with fewer iterations.

Reducing Defects and Waste Through Predictive Analytics

Predictive analytics is another area where AI enhances 3D printing accuracy. By analyzing historical data from previous prints, intelligent systems can forecast potential issues before they occur. This capability is especially valuable in high-volume or mission-critical applications, where even minor defects can lead to costly failures.

By continuously learning from new data, AI systems become better at predicting and preventing defects over time. This not only reduces material waste but also shortens lead times and lowers production costs. Manufacturers can shift from a reactive to a proactive quality assurance model, ensuring that each print meets the required specifications.

Automated Post-Processing and Inspection

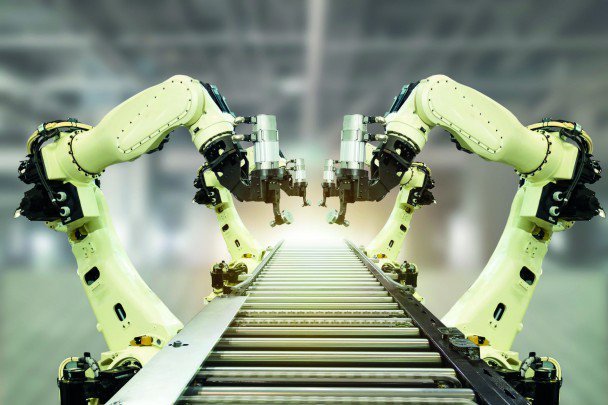

Quality assurance does not end when the printing process is complete. Post-processing steps such as support removal, surface finishing, and dimensional inspection are critical for ensuring that parts meet functional and aesthetic standards. AI-powered vision systems and robotics can automate these tasks, increasing throughput and reducing the risk of human error.

Advanced image recognition algorithms can quickly identify surface defects, measure tolerances, and verify that parts conform to digital models. This level of automation allows for 100% inspection of every component, even in large production runs, without slowing down the workflow.

Integrating AI with IoT for Smarter Manufacturing

The combination of AI and the Industrial Internet of Things (IIoT) is pushing the boundaries of what is possible in additive manufacturing. Connected devices collect real-time data from printers, materials, and the production environment, feeding this information into AI systems for analysis and optimization. This holistic approach enables manufacturers to monitor the entire lifecycle of a part, from design to delivery.

If you’re interested in learning more about this synergy, our article on industrial internet of things and AI offers a deeper look at how connected technologies are creating smarter, more responsive factories.

Benefits of AI-Enhanced 3D Printing Quality Control

The advantages of integrating artificial intelligence into additive manufacturing quality control are substantial:

- Higher consistency across production runs

- Reduced material waste and lower costs

- Faster identification and correction of defects

- Improved design optimization and functional performance

- Automated inspection for greater efficiency

- Predictive maintenance to minimize downtime

These benefits are driving adoption of AI-powered solutions in industries where precision and reliability are non-negotiable.

Challenges and Considerations in AI-Driven 3D Printing

While the advantages are clear, implementing AI in additive manufacturing is not without challenges. Data quality and availability are critical—AI systems require large, accurate datasets to function effectively. Integrating new technologies with existing workflows can also be complex, requiring investment in both hardware and training.

Additionally, maintaining transparency and explainability in AI-driven decisions is important, especially in regulated industries. Manufacturers must ensure that automated quality control processes are auditable and compliant with industry standards.

For a broader perspective on the impact of smart technologies in manufacturing, you may find value in reading about the benefits of combining AI and IoT in manufacturing.

Future Trends in AI and Additive Manufacturing

The future of 3D printing will be shaped by continued advances in artificial intelligence. As machine learning models become more sophisticated, we can expect even greater levels of automation, accuracy, and customization. Emerging trends include:

- Real-time adaptive printing, where AI adjusts parameters on the fly for optimal results

- Deeper integration with digital twins for virtual testing and validation

- Expansion of AI-driven generative design for highly complex, functional parts

- Greater use of cloud-based analytics for collaborative manufacturing

These innovations will further cement the role of intelligent systems in achieving the highest standards of additive manufacturing quality.

For more on how predictive technologies are minimizing downtime and improving reliability, see our article on how AI predicts equipment breakdowns.

Further Reading and Industry Resources

To explore additional applications of smart technologies in manufacturing, consider reading this comprehensive overview of AI in manufacturing for insights into current trends and case studies.

Frequently Asked Questions

How does AI detect defects during 3D printing?

AI systems use sensors, cameras, and machine learning algorithms to monitor the printing process in real time. By analyzing data such as temperature, layer alignment, and material flow, these systems can identify anomalies that indicate potential defects. When an issue is detected, the system can alert operators or automatically adjust printing parameters to correct the problem.

What are the main benefits of using AI in additive manufacturing?

The main benefits include improved consistency, reduced waste, faster defect detection, optimized design, automated inspection, and predictive maintenance. These advantages help manufacturers achieve higher quality standards and lower production costs.

Can AI be integrated with existing 3D printing equipment?

Yes, AI solutions can often be integrated with existing 3D printers through the addition of sensors, cameras, and software platforms. However, successful implementation may require investment in new hardware and staff training to ensure seamless operation and data quality.