In today’s highly competitive industrial landscape, minimizing mistakes on the production floor is more important than ever. Even minor errors can lead to costly downtime, wasted materials, and compromised product quality. Manufacturers are turning to advanced technologies to address these challenges, and artificial intelligence is at the forefront of this transformation. By leveraging machine learning, computer vision, and data analytics, AI is helping organizations create safer, more efficient, and more reliable manufacturing environments.

This article explores the practical ways that AI-driven systems are reducing mistakes in manufacturing, from real-time monitoring to predictive maintenance and process optimization. For a deeper dive into how digital twins and AI work together to optimize operations, see how digital twins use ai.

Understanding the Impact of Human Error in Manufacturing

Human mistakes have long been a significant source of inefficiency in manufacturing. These errors can arise from fatigue, distraction, miscommunication, or lack of training. The consequences range from minor defects to major safety incidents and production stoppages. Traditional quality control methods, while helpful, often fail to catch every issue—especially in fast-paced or complex environments.

As factories become more automated and interconnected, the margin for error shrinks. This is where AI-powered solutions come into play, offering new ways to detect, prevent, and correct mistakes before they escalate.

Key Ways Artificial Intelligence Minimizes Mistakes on the Factory Floor

The integration of AI technologies in manufacturing is reshaping how companies approach quality, safety, and efficiency. Below are some of the most impactful methods by which AI helps reduce errors:

- Automated Quality Inspection: Computer vision systems can analyze products in real time, identifying defects that human inspectors might miss. These systems learn from vast datasets, improving their accuracy over time and ensuring consistent quality.

- Predictive Maintenance: By monitoring equipment performance and analyzing sensor data, AI can predict when machines are likely to fail. This proactive approach prevents unexpected breakdowns and reduces the risk of human error during manual inspections.

- Process Optimization: Machine learning algorithms analyze production data to identify inefficiencies and recommend adjustments. This helps standardize workflows and minimize variability caused by human intervention.

- Worker Assistance Systems: AI-driven tools provide real-time guidance to operators, flagging potential mistakes and offering corrective suggestions. These systems support less experienced workers and help maintain high standards across shifts.

- Data-Driven Decision Making: By aggregating and analyzing information from across the factory, AI enables managers to make informed decisions that reduce risk and improve outcomes.

Real-World Examples of AI Preventing Mistakes

Many manufacturers have already seen significant benefits from implementing AI-based error reduction strategies. For instance, automotive plants use computer vision to inspect welds and paint jobs, catching flaws that could lead to recalls. Electronics manufacturers deploy machine learning to monitor assembly lines and quickly identify anomalies in circuit board production.

In food processing, AI systems monitor temperature, humidity, and other variables to ensure products meet safety standards. These solutions not only reduce the risk of contamination but also free up human workers to focus on higher-value tasks.

For more on how smart factories are evolving, see this resource on the industrial internet of things and ai.

How AI-Driven Monitoring and Analytics Reduce Human Error

One of the most powerful aspects of AI in manufacturing is its ability to monitor processes continuously and analyze vast amounts of data. Unlike manual checks, which are limited by human attention and capacity, AI systems can run 24/7, flagging even subtle deviations from expected patterns.

For example, machine learning models can detect when a machine is operating outside its normal parameters, alerting staff before a problem occurs. This reduces the likelihood of mistakes caused by oversight or delayed response. AI-powered dashboards also present actionable insights, helping teams prioritize interventions and allocate resources more effectively.

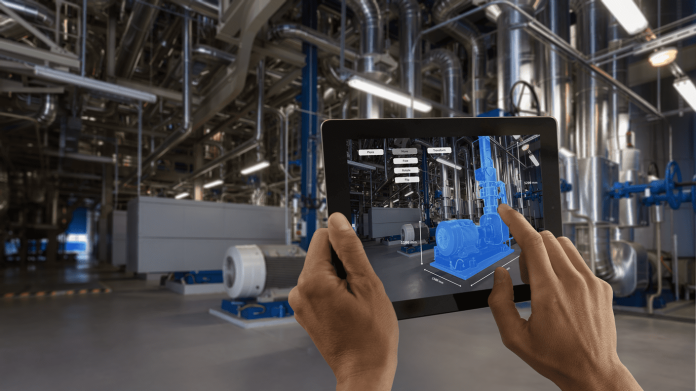

Integrating AI with IoT for Enhanced Error Prevention

The combination of artificial intelligence and IoT devices is creating smarter, more connected factories. Sensors embedded throughout the production line collect real-time data, which AI algorithms analyze to detect trends and anomalies. This integration not only prevents mistakes but also enables rapid response to changing conditions.

Manufacturers interested in the advantages of this approach can learn more from the article on the benefits of combining ai and iot in manufacturing.

Challenges and Considerations When Implementing AI Solutions

While the benefits of reducing errors with AI are clear, successful implementation requires careful planning. Companies must invest in high-quality data, robust infrastructure, and employee training. Change management is also crucial, as workers need to understand and trust new systems.

Security and privacy are additional considerations, especially when integrating AI with IoT. Manufacturers should establish clear protocols for data handling and system updates to minimize vulnerabilities.

For more insights into how AI is transforming the sector, see this overview of AI’s impact on manufacturing.

Looking Ahead: The Future of Error-Free Manufacturing

As AI technologies continue to evolve, their role in minimizing mistakes will only grow. Future advancements may include even more sophisticated predictive analytics, autonomous robots, and seamless integration with supply chain systems. Manufacturers who embrace these innovations will be better positioned to deliver high-quality products, reduce costs, and maintain a competitive edge.

To explore how predictive analytics can further reduce downtime and errors, see the guide on how ai predicts equipment breakdowns.

Frequently Asked Questions

What types of human error can AI help prevent in manufacturing?

AI can help prevent a wide range of mistakes, including incorrect assembly, missed defects during inspections, equipment misconfiguration, and process deviations. By providing real-time monitoring and automated decision support, AI reduces the likelihood of both minor and major errors.

Is it expensive to implement AI for error reduction in factories?

The cost of implementing AI varies depending on the scale and complexity of the solution. While there is an initial investment in technology and training, many manufacturers find that the long-term savings from reduced waste, improved quality, and fewer disruptions outweigh the upfront costs.

How does AI work with existing manufacturing systems?

AI systems are often designed to integrate with existing equipment and software. They can analyze data from sensors, machines, and enterprise resource planning (ERP) systems to provide actionable insights. This allows companies to enhance their current processes without needing to replace all their infrastructure.