Minimizing unplanned stoppages is a top priority for modern factories. As production lines become more complex and customer demands increase, even short interruptions can lead to significant losses in productivity and revenue. Manufacturers are increasingly turning to artificial intelligence to tackle this challenge, leveraging advanced algorithms and real-time data to keep operations running smoothly. This guide explores how AI reduces downtime in manufacturing, highlighting practical strategies, benefits, and real-world applications that are reshaping the industry.

For a deeper dive into related topics, see our article on how predictive maintenance works with AI to prevent equipment failures before they happen.

Understanding Downtime in Industrial Environments

Downtime refers to any period when manufacturing equipment or processes are not operational. This can be caused by unexpected equipment failures, scheduled maintenance, supply chain disruptions, or human error. In highly automated facilities, even brief interruptions can have a ripple effect, halting entire production lines and delaying order fulfillment.

Traditional approaches to minimizing downtime often rely on scheduled maintenance and reactive troubleshooting. While these methods can address some issues, they are limited by their inability to predict failures before they occur or to optimize maintenance schedules based on real-time conditions.

Key Ways AI Minimizes Production Interruptions

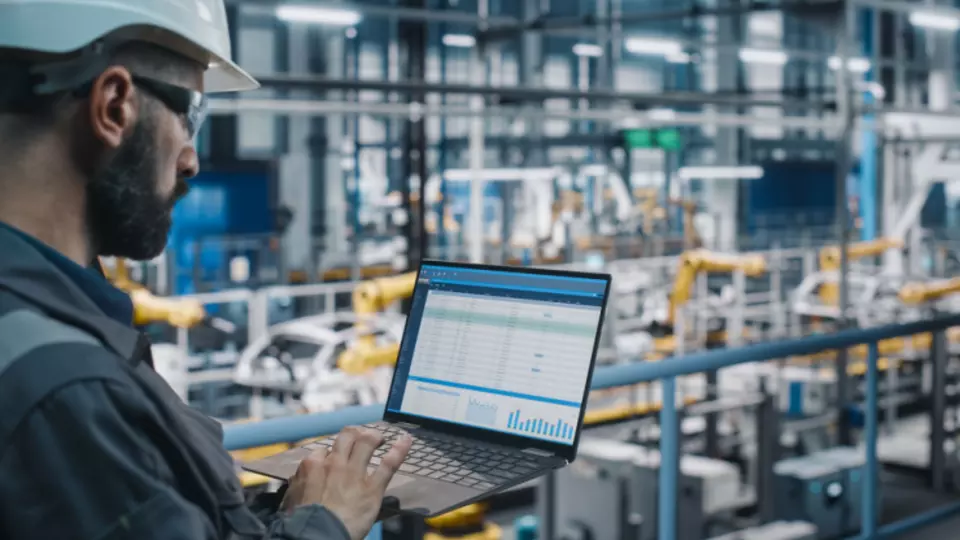

Artificial intelligence is transforming how manufacturers approach operational reliability. By analyzing vast amounts of data from sensors, machines, and enterprise systems, AI can uncover patterns and predict potential issues before they escalate. Here are several ways AI-driven solutions are reducing disruptions on the factory floor:

- Predictive Maintenance: AI-powered systems monitor equipment health in real time, identifying subtle signs of wear or malfunction. This enables maintenance teams to intervene proactively, scheduling repairs only when needed and avoiding unnecessary downtime.

- Automated Root Cause Analysis: When a stoppage occurs, AI can quickly analyze historical and real-time data to pinpoint the underlying cause. This accelerates troubleshooting and helps teams implement lasting solutions.

- Process Optimization: Machine learning algorithms continuously analyze production data to identify inefficiencies, bottlenecks, or deviations from optimal performance. Adjustments can be made automatically or suggested to operators, reducing the risk of unplanned halts.

- Supply Chain Resilience: AI can forecast material shortages or logistics delays, allowing manufacturers to adjust schedules or source alternatives before production is impacted.

Real-World Applications: AI in Action

Many leading manufacturers have already implemented AI-based systems to combat downtime. For example, automotive plants use predictive analytics to monitor robotic arms and conveyor systems, reducing unexpected breakdowns. Food and beverage companies employ AI to optimize cleaning cycles and equipment changeovers, ensuring smooth transitions and minimal stoppages.

For more detailed examples and success stories, explore our resource on examples of AI in manufacturing.

According to industry research, facilities that adopt AI-driven predictive maintenance can reduce unplanned downtime by up to 50%. This not only improves output but also extends equipment lifespan and lowers maintenance costs.

How AI-Powered Predictive Maintenance Prevents Disruptions

One of the most impactful uses of AI in manufacturing is predictive maintenance. By collecting continuous data from sensors embedded in machinery, AI models can detect anomalies that signal impending failures. These systems learn from historical breakdowns, environmental conditions, and usage patterns to refine their predictions over time.

Maintenance teams receive alerts when equipment shows early warning signs, allowing them to plan interventions during scheduled downtimes rather than reacting to emergencies. This approach not only reduces the frequency and duration of stoppages but also helps allocate resources more efficiently.

Integrating AI with Existing Manufacturing Systems

Implementing AI solutions does not require a complete overhaul of existing infrastructure. Many modern platforms are designed to integrate seamlessly with legacy equipment and enterprise resource planning (ERP) systems. Data from sensors, PLCs, and MES platforms can be aggregated and analyzed in real time, providing actionable insights without disrupting ongoing operations.

For manufacturers interested in future-proofing their operations, it’s important to consider how AI can complement other digital transformation initiatives. Learn more about upcoming trends and innovations in our article on the future of AI in manufacturing.

Benefits of Reducing Downtime with AI

The advantages of leveraging AI to minimize production interruptions extend beyond immediate cost savings. Key benefits include:

- Increased Productivity: Fewer stoppages mean higher throughput and more consistent delivery schedules.

- Lower Maintenance Costs: Targeted, condition-based maintenance reduces unnecessary part replacements and labor expenses.

- Improved Product Quality: Consistent operations help maintain quality standards and reduce the risk of defects caused by sudden halts.

- Enhanced Worker Safety: Proactive maintenance and automated monitoring reduce the likelihood of accidents related to equipment failure.

- Data-Driven Decision Making: Continuous monitoring and analysis empower managers to make informed choices about process improvements and resource allocation.

Challenges and Considerations When Adopting AI

While the benefits are clear, integrating AI into manufacturing environments does present some challenges. Data quality and availability are critical—AI models require accurate, high-resolution data to deliver reliable predictions. Additionally, change management and workforce training are essential to ensure that teams can effectively use new tools and processes.

Manufacturers should also evaluate the scalability and interoperability of AI solutions, ensuring they align with long-term business goals. For a comprehensive overview of how these technologies are being implemented, see this resource on AI in manufacturing from SAP.

Looking Ahead: The Evolving Role of AI in Manufacturing

As AI technologies continue to advance, their role in minimizing downtime will only grow. Future developments may include self-healing systems, autonomous production lines, and even greater integration with supply chain management. Manufacturers that invest in AI today will be better positioned to adapt to changing market conditions and maintain a competitive edge.

For insights into how machine learning is optimizing factory processes, check out our guide on how machine learning works in factories.

Frequently Asked Questions

What types of manufacturing downtime can AI help prevent?

AI can address a wide range of interruptions, including equipment failures, process bottlenecks, supply chain disruptions, and quality control issues. By analyzing real-time and historical data, AI systems can predict and prevent many common causes of unplanned stoppages.

How does predictive maintenance differ from traditional maintenance?

Traditional maintenance often follows a fixed schedule or responds to breakdowns after they occur. Predictive maintenance, powered by AI, uses real-time data to anticipate failures and schedule repairs only when necessary, reducing unnecessary downtime and maintenance costs.

Is it expensive to implement AI solutions in existing factories?

The cost of implementing AI varies depending on the scale and complexity of the operation. Many solutions are designed to integrate with existing equipment, minimizing upfront investment. Over time, the reduction in downtime and maintenance expenses can deliver a strong return on investment.

Where can I learn more about practical AI applications in manufacturing?

For more real-world examples and case studies, visit our article on examples of AI in manufacturing.