Maximizing the use of industrial assets is a top priority for manufacturers and operations managers. As production demands rise and competition intensifies, organizations are turning to advanced technologies to get more from their existing machinery. How AI improves equipment utilization is a topic gaining traction, as artificial intelligence offers practical solutions to longstanding challenges in asset management, maintenance, and process optimization.

By leveraging AI-driven insights, companies can identify inefficiencies, reduce downtime, and ensure that every piece of equipment contributes to higher throughput and quality. This guide explores the main ways AI transforms equipment usage, offering actionable strategies and real-world examples. For a deeper look at related manufacturing innovations, consider reading about the role of AI in lean manufacturing and how it streamlines operations efficiently.

Understanding Equipment Utilization and Its Challenges

Equipment utilization measures how effectively assets are used compared to their full potential. High utilization means machines spend more time producing and less time idle. However, achieving optimal usage is not always straightforward. Common obstacles include:

- Unplanned downtime due to unexpected failures

- Inefficient scheduling or bottlenecks in production lines

- Lack of real-time visibility into machine status

- Manual data collection leading to errors and delays

- Reactive rather than proactive maintenance strategies

Traditional methods often fall short in addressing these issues, especially as operations scale. This is where artificial intelligence steps in, offering data-driven approaches that enhance decision-making and operational efficiency.

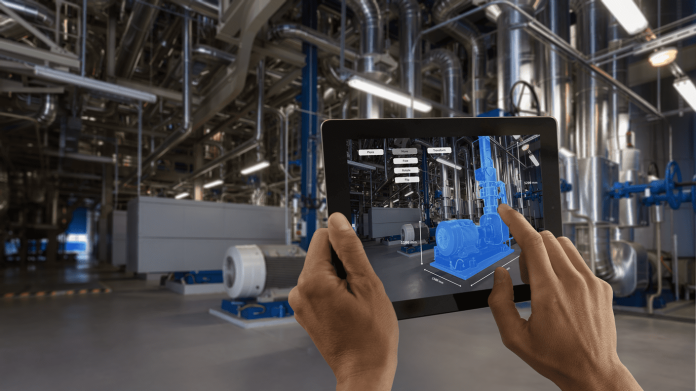

AI-Powered Monitoring for Real-Time Insights

One of the most significant contributions of AI is its ability to provide continuous, real-time monitoring of equipment. By integrating sensors and IoT devices, AI systems collect vast amounts of operational data—temperature, vibration, run time, and more. Machine learning algorithms analyze this data to detect patterns and anomalies that humans might miss.

With these insights, managers can quickly identify underperforming assets, spot early warning signs of potential failures, and make informed decisions about resource allocation. For example, if a particular machine is consistently running below capacity, AI can highlight this trend and suggest corrective actions.

Predictive Maintenance: Reducing Downtime and Extending Asset Life

Downtime is a major contributor to poor equipment utilization. Traditional maintenance schedules are often based on fixed intervals or reactive repairs after a breakdown. AI changes this dynamic through predictive maintenance, which uses data analytics to forecast when a machine is likely to fail.

By analyzing historical and real-time data, AI models can predict wear and tear, enabling maintenance teams to intervene before a breakdown occurs. This proactive approach minimizes unplanned downtime, reduces repair costs, and ensures that equipment remains available for production.

Predictive maintenance also helps organizations optimize spare parts inventory and labor planning, further improving operational efficiency. For more on how data collection supports these strategies, explore AI in manufacturing data collection for smarter insights and control.

Optimizing Scheduling and Resource Allocation with AI

Efficient scheduling is critical for maximizing equipment usage. AI algorithms can analyze production requirements, machine availability, and workforce constraints to develop optimal schedules. By dynamically adjusting plans in response to real-time events—such as machine breakdowns or rush orders—AI ensures that resources are allocated where they are needed most.

This level of automation reduces idle time and bottlenecks, allowing organizations to respond quickly to changing demands. The result is a more agile and productive operation, with higher throughput and less waste.

Enhancing Output Quality and Consistency

Consistent output quality is essential for customer satisfaction and regulatory compliance. AI-driven systems monitor process parameters and product characteristics in real time, identifying deviations that could impact quality. By making automatic adjustments or alerting operators, AI helps maintain optimal conditions throughout the production cycle.

This not only improves product quality but also reduces rework and scrap, further enhancing equipment utilization. For a closer look at how AI supports quality assurance, see the article on how AI detects defects in manufacturing for improved quality.

Data-Driven Decision Making for Continuous Improvement

The integration of AI into manufacturing operations enables a culture of continuous improvement. By providing actionable insights and performance analytics, AI empowers managers to make evidence-based decisions. Over time, this leads to incremental gains in efficiency, reduced costs, and higher output.

For example, AI can identify which machines are consistently underutilized and recommend process changes or retraining for operators. It can also highlight opportunities to shift production loads, balance workflows, or invest in targeted upgrades.

Industry Examples and Real-World Impact

Many leading manufacturers have already realized significant benefits by adopting AI-driven solutions. According to industry research on AI’s impact in manufacturing, companies report measurable improvements in asset uptime, production flexibility, and cost control.

In sectors ranging from automotive to electronics, AI-powered monitoring and predictive maintenance have reduced unplanned downtime by up to 30%. Scheduling optimization tools have helped factories increase throughput without additional capital investment. These results demonstrate the practical value of embracing AI for equipment management.

Integrating AI with Lean and Just-in-Time Practices

AI technologies complement established manufacturing methodologies such as lean and just-in-time (JIT) production. By providing real-time data and predictive analytics, AI enhances the ability to eliminate waste, synchronize workflows, and respond to demand fluctuations.

To learn how AI supports JIT strategies and reduces waste, visit the guide on how AI supports just in time production. Integrating these approaches creates a robust framework for maximizing equipment effectiveness and delivering consistent results.

FAQ

What types of equipment benefit most from AI-driven utilization strategies?

AI can enhance utilization for a wide range of assets, including CNC machines, assembly robots, conveyor systems, and industrial ovens. Any equipment that generates operational data or is part of a production line can benefit from AI-powered monitoring, predictive maintenance, and scheduling optimization.

How does AI reduce unplanned downtime in manufacturing?

AI analyzes real-time and historical data to detect early warning signs of equipment failure. By predicting when maintenance is needed, AI enables proactive interventions, reducing the risk of unexpected breakdowns and keeping machines running longer.

Is it difficult to implement AI solutions for equipment management?

Implementation complexity varies depending on existing infrastructure and data availability. Many modern AI platforms are designed for seamless integration with industrial IoT devices and manufacturing execution systems. Starting with pilot projects and scaling gradually is a common approach for successful adoption.