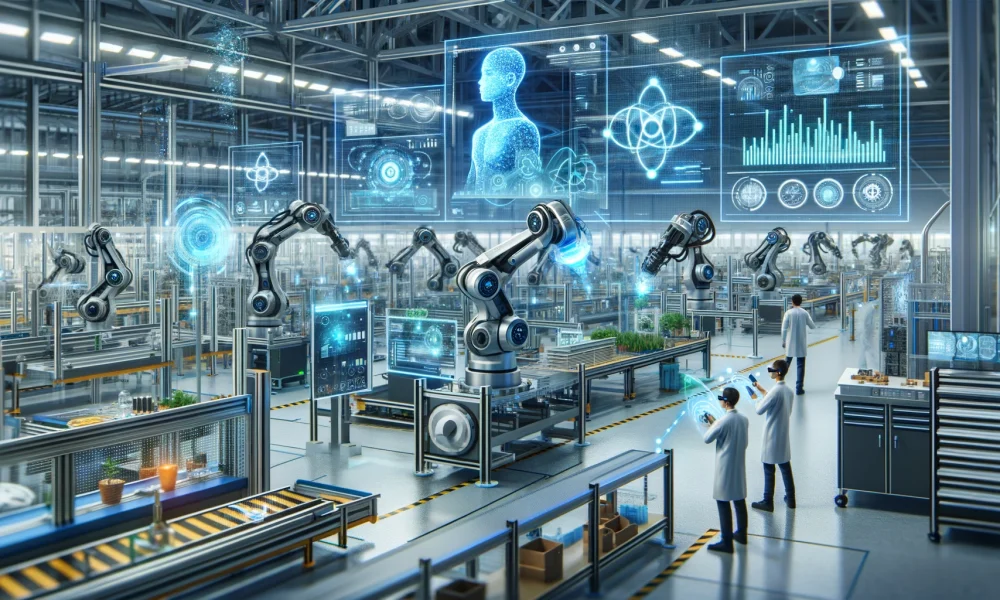

The manufacturing sector is undergoing a significant transformation as artificial intelligence (AI) becomes increasingly integrated into production environments. By leveraging advanced algorithms, machine learning, and real-time data analysis, manufacturers are unlocking new levels of efficiency, quality, and flexibility. The applications of AI in production lines are reshaping traditional processes and setting new standards for smart manufacturing.

As companies strive to remain competitive, the adoption of AI-driven solutions is no longer a futuristic concept but a practical necessity. From predictive maintenance to automated quality control, these intelligent systems are helping organizations reduce downtime, minimize waste, and optimize resource allocation. For a deeper look at how these innovations compare to older methods, you can explore the difference between smart manufacturing and traditional manufacturing.

Key Ways Artificial Intelligence Enhances Manufacturing Processes

Integrating AI into manufacturing lines brings a range of tangible benefits. These improvements are not limited to automation but extend to smarter decision-making, predictive insights, and adaptive control. Below are some of the most impactful areas where AI is making a difference.

Predictive Maintenance and Equipment Monitoring

One of the most valuable applications of AI in production lines is predictive maintenance. By analyzing sensor data and historical trends, AI systems can forecast when machines are likely to fail or require servicing. This approach enables manufacturers to schedule maintenance proactively, reducing unexpected breakdowns and costly downtime.

Predictive models help optimize spare parts inventory and extend equipment lifespan. For a comprehensive understanding of how these systems work, see this guide on how predictive maintenance works with AI.

Automated Quality Control and Inspection

Ensuring product consistency and minimizing defects are critical in manufacturing. AI-powered vision systems and machine learning algorithms can inspect products in real time, identifying flaws that might escape human inspectors. These systems adapt to new defect types, learn from past data, and provide detailed analytics for continuous improvement.

Automated inspection not only improves accuracy but also speeds up the quality assurance process. To learn more about these advancements, visit the article on AI in quality control.

Process Optimization and Real-Time Decision Making

AI-driven analytics enable manufacturers to optimize production parameters on the fly. By continuously monitoring variables such as temperature, pressure, and speed, intelligent systems can suggest or automatically implement adjustments to maximize output and minimize waste. This level of process control leads to higher yields and more consistent product quality.

Real-time data analysis supports faster, more informed decisions, allowing production lines to adapt quickly to changing conditions or customer demands.

How AI Improves Productivity and Reduces Downtime

The integration of AI technologies into manufacturing lines is directly linked to increased productivity and reduced operational interruptions. By automating routine tasks and providing actionable insights, AI allows human workers to focus on higher-value activities.

Minimizing Production Interruptions

AI systems can detect anomalies in equipment behavior or production output, triggering alerts before minor issues escalate into major problems. This proactive approach helps maintain steady production flow and reduces the risk of unplanned stoppages. More details on this topic can be found in the article about how AI reduces downtime in manufacturing.

Boosting Efficiency Through Data-Driven Insights

By collecting and analyzing vast amounts of production data, AI tools identify inefficiencies and recommend process improvements. These insights can lead to better resource allocation, reduced energy consumption, and optimized scheduling. Over time, these incremental gains add up to significant cost savings and productivity boosts.

Enhancing Collaboration Between Humans and Machines

Modern manufacturing environments are increasingly collaborative, with AI systems supporting human workers rather than replacing them. Intelligent robots and cobots (collaborative robots) can handle repetitive, hazardous, or precision tasks, while humans oversee complex problem-solving and creative decision-making. This synergy leads to safer workplaces and higher overall productivity.

Real-World Examples of AI in Manufacturing

Across various industries, companies are already seeing measurable benefits from adopting AI on their production lines. For instance, automotive manufacturers use computer vision for paint inspection and assembly verification, while electronics producers rely on machine learning to optimize component placement and reduce defects.

Food and beverage companies employ AI to monitor freshness, automate sorting, and ensure compliance with safety standards. These real-world applications demonstrate the versatility and value of intelligent technologies in diverse manufacturing settings.

Challenges and Considerations for AI Adoption

While the benefits are clear, implementing AI in manufacturing is not without challenges. Integrating new technologies with legacy systems, ensuring data quality, and addressing workforce skill gaps require careful planning. Security and privacy concerns must also be addressed, especially when dealing with sensitive production data.

Organizations should start with pilot projects, invest in employee training, and work with experienced partners to ensure successful AI integration. For a broader perspective on the impact of these technologies, see the article on the impact of AI on industrial productivity.

Further Reading and Industry Resources

For those interested in exploring the broader implications and future trends, the role of AI in the manufacturing industry provides valuable insights into how these technologies are shaping the sector globally.

Frequently Asked Questions

What are the main benefits of using AI in production lines?

The primary advantages include improved efficiency, reduced downtime, enhanced product quality, and better resource utilization. AI systems enable predictive maintenance, automate quality control, and provide real-time insights that help manufacturers optimize their operations.

How does AI-powered quality control differ from traditional inspection methods?

AI-powered quality control uses machine vision and learning algorithms to inspect products at high speed and with greater accuracy than manual inspection. These systems can adapt to new defect types, learn from historical data, and provide detailed analytics, resulting in more consistent product quality and faster detection of issues.

What challenges should manufacturers consider when implementing AI?

Key challenges include integrating AI with existing systems, ensuring high-quality data, addressing workforce training needs, and managing cybersecurity risks. Starting with small-scale projects and gradually scaling up can help organizations overcome these hurdles and realize the full benefits of AI.