Managing inventory efficiently is a challenge faced by businesses of all sizes. Overstocking ties up capital and storage space, while stockouts can lead to lost sales and dissatisfied customers. In recent years, ai in inventory management has emerged as a transformative solution, allowing companies to balance supply and demand with greater precision. By leveraging advanced algorithms and real-time data, artificial intelligence is helping organizations reduce waste, optimize stock levels, and streamline their entire supply chain.

This article explores how artificial intelligence is changing the way companies handle their inventories, from demand forecasting to automated replenishment. We’ll look at the key benefits, practical applications, and steps to get started with AI-powered inventory solutions. For those interested in broader applications of smart technology in manufacturing, you might also find value in learning about how digital twins use AI to optimize operations.

How Artificial Intelligence Transforms Inventory Control

Traditional inventory management often relies on manual processes and static rules, which can be slow to adapt to changing market conditions. With the integration of ai in inventory management, businesses gain access to predictive analytics and automation tools that can process vast amounts of data in real time. This shift enables more accurate forecasting, dynamic stock adjustments, and a reduction in both excess inventory and shortages.

AI-powered systems analyze historical sales, seasonal trends, supplier lead times, and even external factors like weather or market shifts. By continuously learning from new data, these systems improve their predictions and recommendations, helping companies make smarter purchasing and stocking decisions.

Key Benefits of AI-Driven Inventory Optimization

Implementing artificial intelligence in inventory processes offers several clear advantages:

- Improved Demand Forecasting: AI models can identify patterns and predict future sales more accurately than traditional methods, reducing the risk of overstocking or running out of products.

- Automated Replenishment: Intelligent systems can trigger purchase orders or production runs automatically when stock levels reach predefined thresholds, minimizing manual intervention.

- Waste Reduction: By aligning inventory with actual demand, companies can cut down on expired, obsolete, or unsold goods, leading to significant cost savings and environmental benefits.

- Enhanced Visibility: Real-time dashboards and analytics provide a clear view of inventory across multiple locations, enabling faster and better-informed decisions.

- Supply Chain Resilience: AI can quickly adapt to disruptions, such as supplier delays or sudden changes in demand, helping businesses maintain service levels even in uncertain times.

For a deeper dive into how smart technologies are making factories more connected and efficient, explore the topic of industrial internet of things and AI.

Practical Applications of AI in Stock Management

The use of artificial intelligence in inventory management is not limited to large enterprises. Businesses of all sizes are adopting these tools to gain a competitive edge. Here are some practical ways AI is being used:

- Dynamic Pricing: AI algorithms can adjust product prices based on real-time demand, inventory levels, and competitor activity, helping to maximize revenue and reduce excess stock.

- Supplier Management: Intelligent systems evaluate supplier performance, lead times, and reliability, recommending the best partners and negotiating optimal terms.

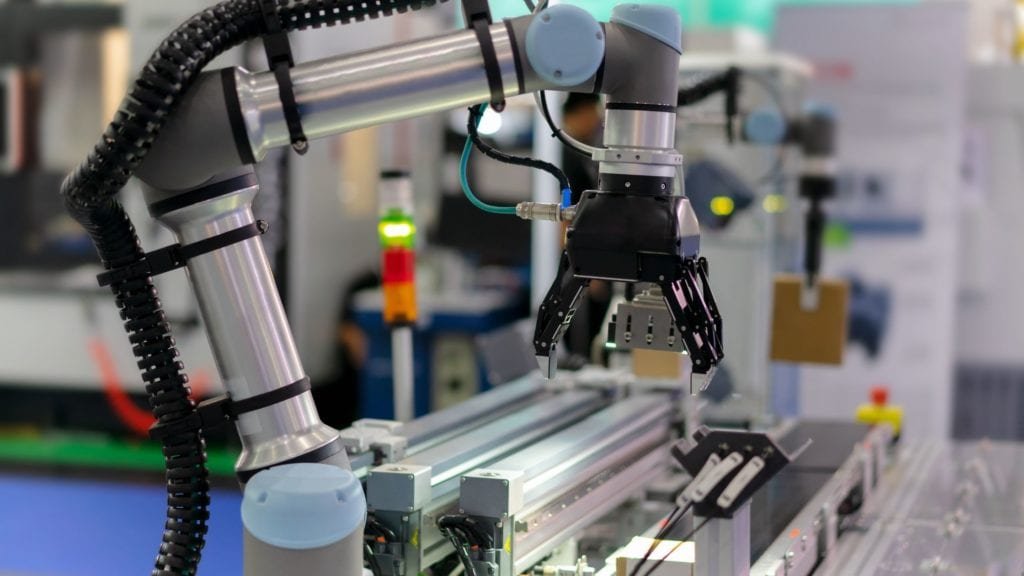

- Warehouse Automation: Robotics and AI-powered picking systems streamline order fulfillment, reduce errors, and optimize storage space.

- Risk Detection: AI can flag potential issues such as fraud, theft, or process bottlenecks, allowing for proactive intervention.

Steps to Implement AI in Your Inventory Processes

Adopting AI for inventory control requires careful planning and a phased approach. Here’s how organizations can get started:

- Assess Current Systems: Review your existing inventory management processes and identify areas where automation or predictive analytics could add value.

- Gather and Clean Data: AI relies on accurate, comprehensive data. Ensure your sales, supplier, and inventory records are up to date and consistent.

- Select the Right Tools: Evaluate AI-powered inventory solutions that integrate with your current software and meet your business needs.

- Pilot and Measure: Start with a pilot program in a specific product line or location. Monitor results, adjust parameters, and measure improvements in stock levels, waste, and service rates.

- Scale and Optimize: Once proven, roll out AI-driven inventory management across your organization, continuously refining models and processes for maximum benefit.

Companies interested in combining AI with other smart technologies can learn more about the benefits of combining AI and IoT in manufacturing for even greater efficiency.

Challenges and Considerations When Adopting AI Solutions

While the advantages are significant, implementing artificial intelligence in inventory management also comes with challenges:

- Data Quality: Inaccurate or incomplete data can lead to poor predictions and suboptimal decisions.

- Integration Complexity: Connecting AI tools with legacy systems and existing workflows may require technical expertise and investment.

- Change Management: Employees may need training and support to adapt to new processes and trust AI-driven recommendations.

- Cost: While AI solutions can deliver strong ROI, upfront costs for software, hardware, and implementation should be considered.

For a broader perspective on how artificial intelligence is shaping the manufacturing sector, including inventory and beyond, see this overview of AI in manufacturing from industry experts.

Future Trends in AI-Powered Inventory Management

The future of inventory optimization is closely tied to advancements in artificial intelligence and related technologies. Some emerging trends include:

- Real-Time Supply Chain Visibility: AI will increasingly connect data from suppliers, warehouses, and retailers for end-to-end transparency.

- Autonomous Warehousing: Robotics and machine learning will automate more tasks, from receiving goods to shipping orders.

- Personalized Inventory Strategies: AI will tailor stock levels and replenishment cycles to specific locations, customer segments, or even individual buyers.

- Integration with IoT: Sensors and connected devices will feed real-time data into AI systems, further improving accuracy and responsiveness. For more on this, explore how AI integrates with IoT to enhance manufacturing efficiency.

Frequently Asked Questions

How does AI improve demand forecasting in inventory management?

Artificial intelligence analyzes large volumes of historical sales data, market trends, and external factors to predict future demand with greater accuracy. This helps businesses maintain optimal stock levels, reducing both overstock and stockouts.

Can small businesses benefit from AI-driven inventory solutions?

Yes, small and medium-sized businesses can leverage cloud-based AI tools that are affordable and scalable. These solutions help automate routine inventory tasks, improve accuracy, and free up staff for higher-value activities.

What are the main challenges when implementing AI in inventory processes?

The primary challenges include ensuring high-quality data, integrating new tools with existing systems, managing change among staff, and justifying the initial investment. Careful planning and phased implementation can help overcome these obstacles.