The integration of AI in assembly robots is transforming manufacturing, enabling production lines to achieve new levels of intelligence, efficiency, and safety. As industries look for ways to stay competitive, artificial intelligence is becoming a crucial element in automating complex assembly tasks, reducing human error, and adapting to rapidly changing demands. This article explores how smart robotics are reshaping assembly processes, the benefits they bring, and practical steps for manufacturers considering this technology.

Companies adopting these advanced solutions are seeing improvements not only in speed and precision but also in workplace safety and operational flexibility. For those interested in broader applications, our guide on role of ai in lean manufacturing provides additional insights into how artificial intelligence streamlines operations across different manufacturing environments.

How Artificial Intelligence Enhances Assembly Robotics

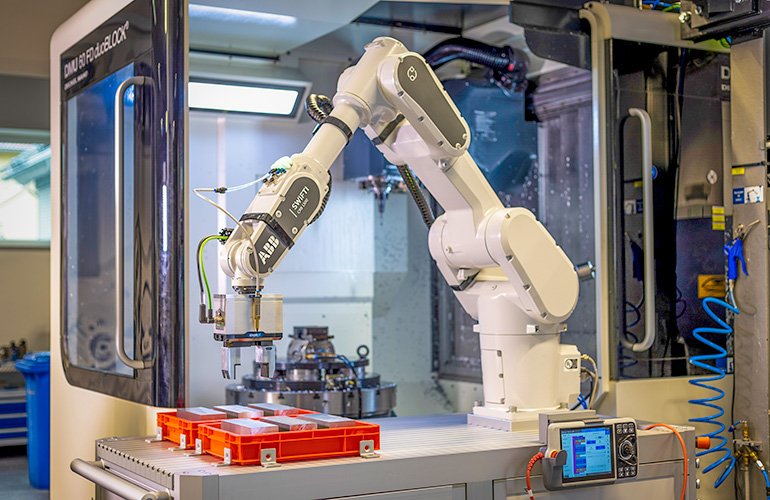

The use of artificial intelligence in assembly robots goes far beyond simple automation. Traditional robots follow pre-programmed instructions, but with AI, machines can interpret sensor data, learn from experience, and adapt to new situations. This capability is especially valuable in assembly lines, where product variations and unexpected issues are common.

- Vision systems powered by AI allow robots to identify, sort, and handle parts with high accuracy.

- Machine learning algorithms enable robots to optimize their movements and assembly sequences over time.

- Predictive maintenance uses AI to monitor robot health and anticipate failures before they cause downtime.

These advancements result in fewer errors, less waste, and a more agile manufacturing process. For example, when a robot equipped with AI vision detects a misaligned component, it can adjust its approach or alert a human operator, preventing defects from moving down the line.

Key Benefits of Smarter Assembly Automation

Manufacturers implementing ai in assembly robots are realizing a range of benefits that extend across the entire production floor. Some of the most significant advantages include:

- Increased Productivity: AI-driven robots work faster and more consistently than manual labor, often running 24/7 with minimal supervision.

- Enhanced Quality: Advanced sensors and real-time data analysis help maintain tight tolerances and reduce the risk of defects.

- Improved Safety: Robots can take on hazardous or repetitive tasks, reducing the risk of workplace injuries and allowing human workers to focus on higher-value activities.

- Greater Flexibility: AI enables robots to switch between different products or assembly tasks with minimal reprogramming, supporting just-in-time and customized manufacturing.

- Lower Operational Costs: By minimizing errors and downtime, AI-powered automation can reduce waste and maintenance expenses.

These benefits are not limited to large corporations. Small and medium-sized manufacturers are also leveraging AI to compete more effectively and respond quickly to market changes. For a deeper look at how smart technologies support lean and just-in-time strategies, see our article on how ai supports just in time production.

Safety Improvements Through AI-Driven Robotics

One of the most impactful changes brought by ai in assembly robots is the improvement in workplace safety. By taking over dangerous or ergonomically challenging tasks, robots reduce the likelihood of injuries. AI further enhances safety by enabling robots to sense their environment and react to unexpected obstacles or human presence.

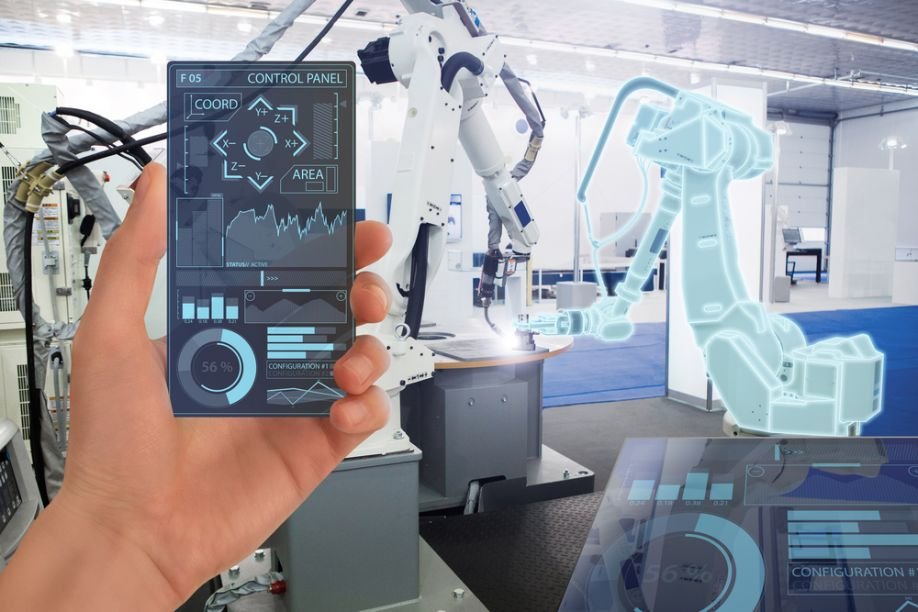

Modern assembly robots use advanced sensors and real-time data processing to detect people, objects, or changes in their workspace. If a human enters a restricted area, the robot can slow down, stop, or reroute its movements to avoid collisions. This collaborative approach, known as “cobotics,” allows humans and robots to work side by side safely.

Additionally, AI-powered robots can analyze safety data to identify patterns and suggest improvements to workflows or workstation layouts. This proactive approach helps prevent accidents before they occur and supports ongoing safety training for staff.

Accelerating Production with Intelligent Automation

Speed is a critical factor in modern manufacturing, and intelligent automation is helping companies meet tight deadlines without sacrificing quality. AI enables robots to optimize their assembly routines, minimize idle time, and quickly adapt to new products or changes in demand.

For example, when a new product variant is introduced, AI can help robots learn the new assembly steps from digital models or sensor feedback, reducing the time needed for reprogramming. This flexibility is essential for manufacturers facing shorter product life cycles and increasing customization requests.

To further explore how data and analytics drive smarter production, our article on ai in manufacturing data collection provides practical examples of how real-time insights support continuous improvement.

Implementing AI Solutions in Assembly Lines

Adopting AI-powered robotics in assembly operations involves several key steps. Manufacturers should start by identifying repetitive or error-prone tasks that could benefit from automation. Next, it’s important to assess the current infrastructure and determine the level of integration required with existing systems.

- Evaluate Needs: Analyze production data to pinpoint bottlenecks, quality issues, or safety risks that AI could address.

- Select the Right Technology: Choose robots and AI platforms that match your product mix and scalability requirements.

- Plan for Integration: Work with technology partners to ensure seamless connectivity with manufacturing execution systems (MES) and quality control processes.

- Train Staff: Equip your workforce with the skills needed to operate, maintain, and collaborate with AI-driven robots.

- Monitor and Optimize: Use analytics to track performance, identify improvement opportunities, and adapt to changing production needs.

For more on how AI can improve machine reliability and performance, see our resource on how ai enhances machine performance.

Challenges and Considerations for Manufacturers

While the advantages of AI-enabled assembly robotics are clear, manufacturers must also consider challenges such as upfront investment, integration complexity, and data security. Selecting the right partners and ensuring robust cybersecurity protocols are essential for long-term success.

Additionally, companies should focus on change management and workforce development to ensure a smooth transition. Involving employees early in the process and providing ongoing training can help build acceptance and maximize the value of new technology.

For a broader perspective on how AI is shaping the future of manufacturing, this overview of AI in manufacturing offers detailed examples and industry trends.

FAQ

What types of assembly tasks benefit most from AI-powered robots?

Tasks that are repetitive, require high precision, or involve complex decision-making are ideal for AI-driven automation. Examples include component placement, quality inspection, and adaptive assembly where product variants frequently change.

How does AI improve safety in assembly operations?

AI enables robots to detect human presence, obstacles, and changes in the environment in real time. This allows for dynamic adjustments to speed, force, or movement, reducing the risk of accidents and supporting safe collaboration between people and machines.

Is AI-based assembly automation suitable for small manufacturers?

Yes, recent advances have made AI-powered robotics more accessible and scalable. Small and medium-sized manufacturers can benefit from improved efficiency, quality, and flexibility, often with modular solutions that fit their specific needs and budgets.

Can AI help with defect detection in assembly lines?

Absolutely. AI-driven vision systems and analytics can identify defects in real time, enabling immediate corrective action. For more details, see our guide on how ai detects defects in manufacturing.