In a monumental step forward, ABB provides a complete range of robots for one of Europes largest kitchen makers, reshaping the landscape of modern kitchen manufacturing. This collaboration is here to usher in a new era of kitchen innovation, harnessing advanced technology to meet growing demands for efficiency and quality.

Why ABB’s Move is Tremendous

The integration of ABBs robotics into kitchen manufacturing represents a tremendous leap forward. These robots offer unprecedented precision, speed, and versatility, crucial for handling complex manufacturing processes. For a company ranked among Europes largest in the kitchen space, this adjustment is both strategic and visionary.

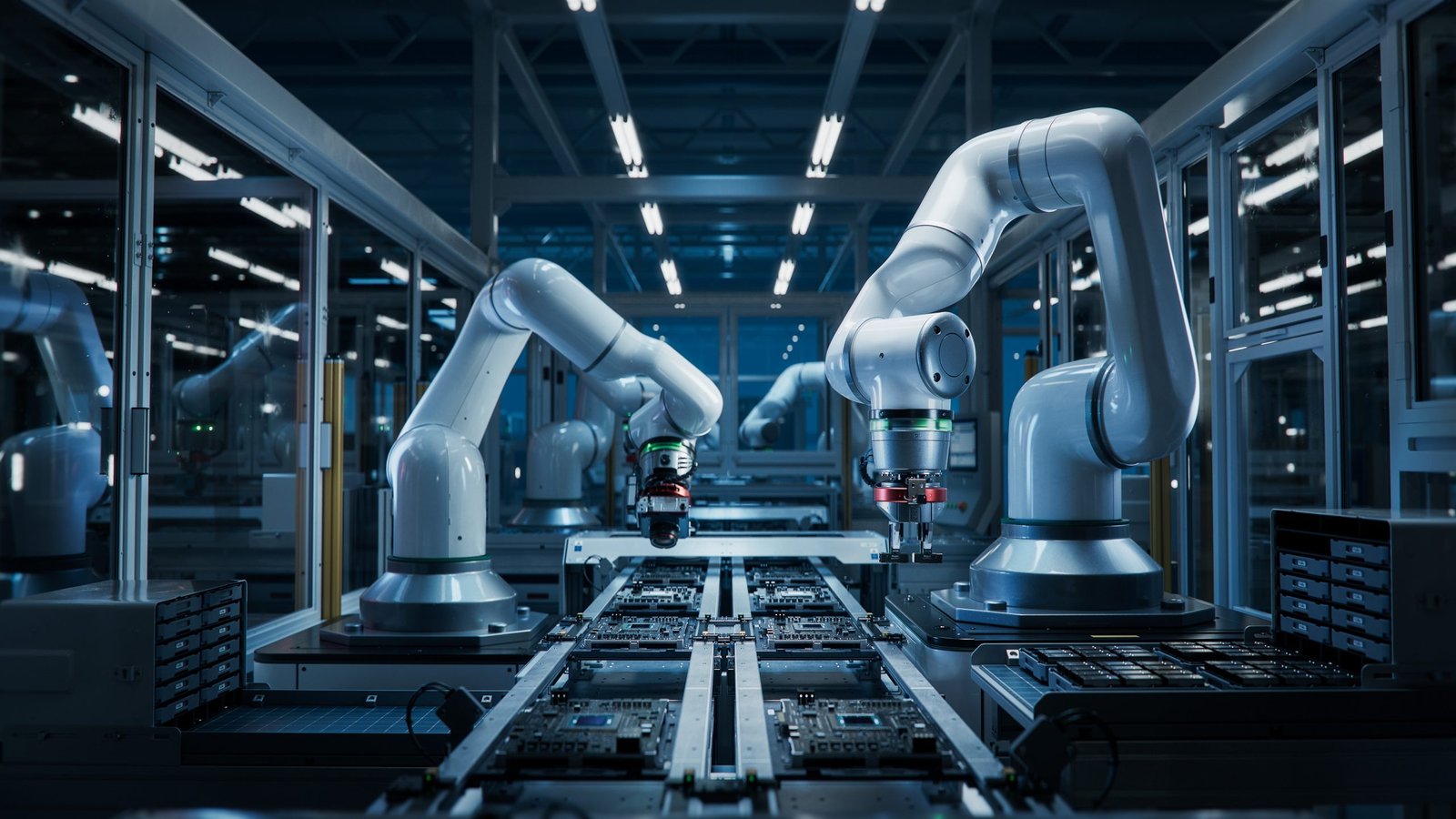

The Robots at Work

ABB‘s robots have been specially designed to handle tasks ranging from assembling cabinets to packaging components. This range of applications not only boosts efficiency but also reduces human error and labor costs, marking a significant enhancement in production capabilities.

Benefits to the Kitchen Industry

The benefits of ABB’s robotic solutions extend beyond simple automation. They incorporate advanced analytics, allowing manufacturers to optimize their workflows and refine production strategies. This enhances overall product quality and increases sustainability in production processes.

Technology that Delights

ABB introduces technology that manufacturers will indeed be delighted with. The robots are equipped to adapt and learn, meaning they better handle variability in the manufacturing environment and contribute to an adaptable, future-proofed production line.

Impact on European Market

This technological upgrade positions European kitchen manufacturers at the forefront of innovation. It not only paves the way for enhanced market competitiveness but also attracts talent interested in cutting-edge industrial automation.

Improving Manufacturing Sustainability

Integrating robots in manufacturing transcends efficiency, offering sustainability benefits through reduced waste and energy consumption. Greater precision in production results in the optimal use of resources, aligning with environmentally-conscious business practices.

The Economic Perspective

Economically, this move helps in scaling production at a lower cost, further strengthening the financial standing of kitchen manufacturers. The initial investment in robotics is outweighed by the long-term benefits of productivity, efficiency, and reduced operational costs.

Exploring Human-Robot Collaboration

While robotics excels in repetitive tasks, human oversight remains crucial for creative and decision-making processes. This balance ensures that employees can focus on more strategic, value-added activities, fostering innovation alongside automation.

Ensuring Quality and Consistency

With robots ensuring uniformity and quality in production, the final products meet high standards consistently. This assures customers of the value and reliability inherent in products produced through automated solutions.

Operational Flexibility and Scalability

ABB’s robots add to the operational flexibility and scalability of manufacturing setups. They can be reprogrammed easily for different tasks, accommodating changes in production needs without significant delays or costs.

Investing in the Future

By investing in such disruptive technologies, kitchen makers safeguard their future growth. Embracing automation is not just about immediate gains but signifies a commitment to long-term industry leadership.

The Bigger Picture

This integration spells a broader acceptance of robotics in industrial applications. As more industries observe the efficiency and reliability of robotic solutions, ABB’s success story could inspire a wave of automation across various sectors.

Learning from ABB’s Success

Companies worldwide can learn from ABB’s approach, adopting similar strategies to enhance their manufacturing processes and stay competitive in fast-evolving markets.

Challenges and Considerations

While robotics offers numerous advantages, ABB and its partners must navigate challenges such as integration complexity and workforce adaptation. Proper training and transparent communication are critical to ensure a smooth transition.

Future-proofing Production

Finally, the collaboration between ABB and Europes leading kitchen maker sets a precedent for future innovation. It’s a tremendous endorsement for integrating advanced robotics to future-proof production capabilities and sustain growth in the competitive marketplace.

Conclusion

In conclusion, ABB provides a complete range of robots for one of Europes largest kitchen makers, transforming their manufacturing landscape with unparalleled efficiency, quality, and innovation. Read more about robotics to see why this move is shaping the future of kitchen manufacturing.

FAQ

What does ABB’s partnership mean for kitchen manufacturing?

ABB’s technology brings automation, efficiency, and innovation, revolutionizing kitchen manufacturing processes.

How do ABB’s robots improve sustainability?

They reduce waste and optimize resource use, thereby enhancing the sustainability of manufacturing operations.

Are human jobs threatened by this rise in automation?

While robotics handle routine tasks, human roles are evolving to focus on strategic and creative activities, emphasizing collaboration over replacement.